Sodium Silicate Sand Casting

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:No.1-101, building no.18, gate no.189, Nanneihuan street, Yinze district, Taiyuan city, Shanxi province, China

- Contact:rayforce com

Other products from Shanxi Rayforce Manufacture Co., Ltd.

Relate products of Sodium Silicate Sand Casting

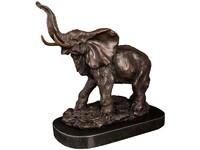

Sand casting china is the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroalloy both can be used to do the sand casting. Types of sand casting is able to produce the part varying from several gram weight to ...

Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, this method of making the casting products is so-called sand casting. There are several different kinds of sand applying to ...

Sodium silicate casting is soluble in water in various amounts. A more common name for sodium silicate is water glass, which is used in iron or steel sand casting. The water glass works as a binder of the sand. It allows the rapid production of a strong Sodium silica sand ...

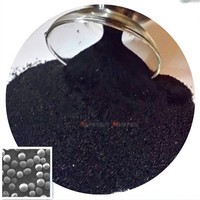

AFS30-35 AFS40-50 AFS40-45 AFS 45-50 chrome iron ore sand for casting SIZES for Chrome Iron Ore Sand: AFS20-25 AFS25-30 AFS30-35 AFS35-40 AFS40-45 AFS45-50 AFS50-55 AFS55-60 AFS60-65 Chemcial index for Chrome Iron Ore Sand: Cr2O3≥46.0% SiO2≤1.0% FeO≤26.5% CaO≤0.30% ...

Sand casting china is the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroalloy both can be used to do the sand casting. Types of sand casting is able to produce the part varying from several gram weight to ...

Resin sand casting is a kind of floor molding process, by mixing the resin with quartz sand and solidification agent, to create the very hard and solid mold. The resulted resin sand casting product will have smooth surfaces, accurate dimensions, and less sand residual and ...

Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, this method of making the casting products is so-called sand casting. There are several different kinds of sand applying to ...

casting ceramic foundry sand for precision casting Ceramisite Sand Ceramic Foundry Sand also named ( Ceracite, Fused Ceramite, Ceramic Sand), It is made of high quality materials by arc melting from bauxite, our Ceramic Foundry Sand with reasonable price, the price is much ...

Ceramic foundry sand for Investment Casting Ceramisite Sand Ceramic Foundry Sand also named ( Ceracite, Fused Ceramite, Ceramic Sand), It is made of high quality materials by arc melting from bauxite, our Ceramic Foundry Sand with reasonable price, the price is much better than ...