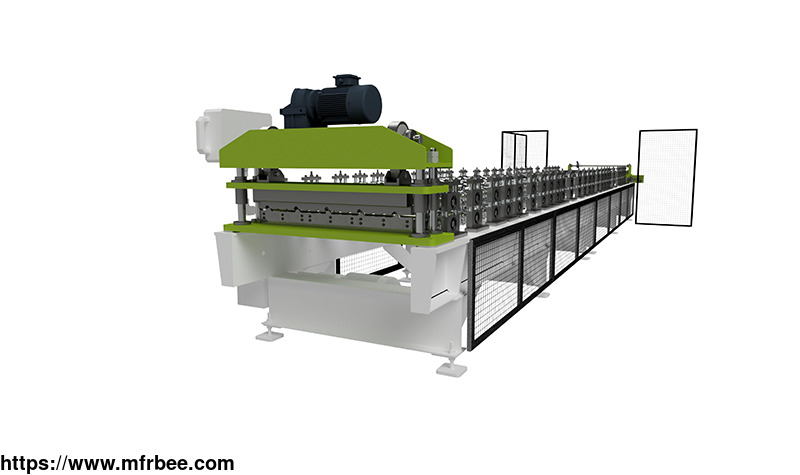

AG PANEL ROLL FORMER

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 60 Days

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Africa

- Founded Year:2003

- Address:

- Contact:hzrollforming .com

You may also like

Other products from Hangzhou Roll Forming Technology Co.,Ltd

Relate products of AG PANEL ROLL FORMER

AG panel roll former is a machine used in the manufacturing process of metal roofing panels. The machine is used to shape flat metal sheets into a corrugated or ribbed pattern that is commonly used in agricultural and industrial settings. Our AG panel roll forming machine ...

Overview of deck roll forming machine The color plate produced by discharging, forming and post-forming cutting has a flat appearance, uniform paint, high strength and durability. Good metal deck roll forming machine is the key to good plate production. The colored steel plate ...

Wall mounted steel enclosure & distribution box door panel roll forming machine production line for electric box outdoor indoor cabinet panel forming and enclosure bending. 1, Steel enclosure production line technical parameters No. ITEM PARAMETER REMARK 1 MATERIAL Type ...

Manual Un-coiler Max Capacity: 5000kgs Inner diameter of coil:400-600mm Manual with brake Leveling Device Ensure the material level and straight The width can be adjusted Main Forming System Width & Height & Thickness of sheet: According to Drawings Material: GI sheet coil or ...

Solar panel structure mounting bracket roll forming machine production line Roll forming machine for production solar bracket named as solar pv bracket, solar photovoltaic bracket. Roll forming machine for solar panel Solar bracket production line process (A) 2 in 1 Uncoiler ...

SPECIFICATIONS FOR YX23-845 Metal Roof Panel Roll Forming Machine DECOILER Manual type no power,5Ton*1200mm coil inner–diameter=508mm; Load capacity= MAX.7.0Ton, Coiler Width= 1200mm Hydraulic type 7Ton*1250mm Load capacity= MAX.7Ton; Hydraulic system expand coil inner ...

Product Application Roll forming Machine for Wall Panel. Product is updated traditional roofing forming machine, the machine mainly by loading rack, loading rack bearing, feeding into platform, forming machine, molding shear device, hydraulic station, computer control box ...

1. Details of roof panel roll forming machine Material Material Thickness(&):0.3 - 0.6mm Applicable material:Galvanized Steel Coils, Hot Rolled Coils,Cold Rolled Coils,yield strength 245Mpa or 550Mpa Machine Components 1)Manual Decoiler: one set Max. feeding width: 500mm, coil ...